Our Supply Chain Ethos

We see our suppliers as our partners working toward a collective goal so that all parties have a mutually beneficial relationship.

More than any other type of textiles industry, the workforce within teamwear is reliant on a skilled team that understands the expectations of the end product. Our capable workforce takes ownership of their work, allowing us to deliver a product with which they are proud to be associated.

Our principles are also aligned in the belief that a good factory has a safe work place. A safe environment is conducive to achieving a vibrant, positive atmosphere that naturally enables a productive work force to create excellent product.

We work side by side to make sure working conditions are met, and we continue to seek the best practices with our partner suppliers. We ensure that our factories strictly comply with local labour laws and seek to exceed these guidelines and regulations.

We selectively work with suppliers that share our values and integrity, as well as our ethos towards how our industry should operate. These relationships have taken time, and we are continuously growing and learning together.

Our Mills

We have a small selection of mills that work with us to deliver the latest in functional, environmentally driven fabrics.

Our fabric is the DNA of our product. It is the cornerstone with which we proudly claim to lead the teamwear market.

Our customised Eco-fit™ fabric collection has such a positive impact on our environmental and sustainability goals that it is key we produce this with the minimum effects on the environment. We are committed to transparency within the supply chain, which allows for us to control the quality of end products while at the same time assuring that production has minimum social impact.

All our fabrics are sent for SGS testing to assure that the fabrics meet our high expectations, as well as industry standards.

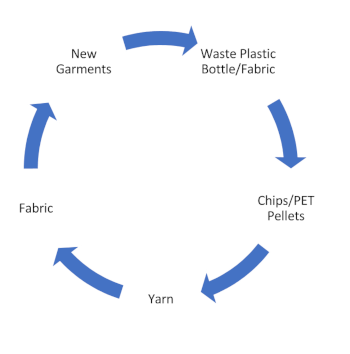

Circular Economy

A major goal of ours is to completely create our customers’ end product from their own plastic and fabric waste. With our method of repurposing PET plastic into functional yarns, this concept is slowly becoming a reality.